Hand wash filling machine

1.Machine dimensions (length × width × height): 3300mm × 1600mm × 2200mm

2. Number of filling heads: 4-24

3. Applicable bottle sizes: Diameter: φ40mm to φ100mm; Height: 80mm to 300mm

4. Bottle opening diameter: ≥φ28mm

5. Filling range: 100ml to 2000ml

6. Production capacity: ≤ 3000 bottles per hour (measured with water)

7. Filling volume error: 1000ml ± 2ml

8. Voltage: 220V; 50HZ

9. Power: 1.5kw

10. Air consumption: 0.55 - 0.65 Mpa of clean and stable compressed air

Hand wash filling machine details:

The hand wash filling machine in our factory was honed through years of hard work in the workshop. While its size might seem impressive (3.3 meters long, 1.6 meters wide, and 2.2 meters high), every dimension is designed for robust production and reliability.

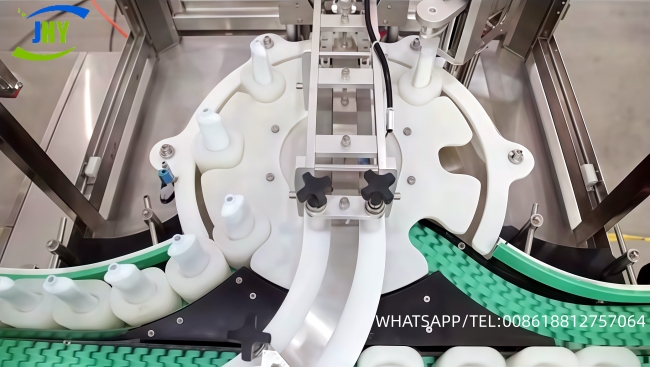

This hand wash filling machine can be configured with up to 24 filling heads. If you're just starting out, start with four heads and then add more as orders increase, without having to replace the entire machine. It also handles a wide range of bottles, including common plastic bottles with diameters ranging from 40 to 100 mm and heights from 80 to 300 mm. As long as the bottle neck is at least 28 mm, it can reliably fill them.

Precision is this machine's strength. When filling 1000 ml, the error is only about ±2 ml, ensuring no overfill or underfill. Material volume control is precise, and especially with today's high raw material costs, greater accuracy means greater savings. The rated speed is no more than 3,000 bottles per hour (this is an ideal value measured using water; actual filling of hand sanitizer will fluctuate slightly due to viscosity). This capacity is sufficient for the daily pace of household hand sanitizer production.

It's not energy-intensive, requiring only 220V standard industrial power with a power of 1.5 kilowatts. The air source requires between 0.55 and 0.65 MPa, which must be clean and stable to ensure consistent machine operation without fluctuating speeds. This machine is robust and can accommodate your business's gradual growth.

The filling valve of this machine features a backflow function, which instantly collects liquid after filling to prevent dripping and keeps the bottle threads dry, making it easy to screw on the cap immediately afterwards without making the bottle sticky. This solves the problem of slippery hand sanitizer contaminating the production line or the bottle during filling.

If your hand sanitizer has varying viscosities or sometimes contains abrasive particles, this hand wash filling machine can adapt by adjusting the air pressure and filling time. It's not a particularly finicky machine.

Overall, this machine is suitable for customers who plan to consistently produce household hand sanitizer and prioritize filling accuracy and bottle cleanliness. If you're interested, please bring a few bottles and hand sanitizers to our factory for a trial run. Filling a few cases and seeing the results is much more intuitive than just listening to me.