This cooking oil filling line is suitable for quantitative filling of various non-gas and semi-fluids.

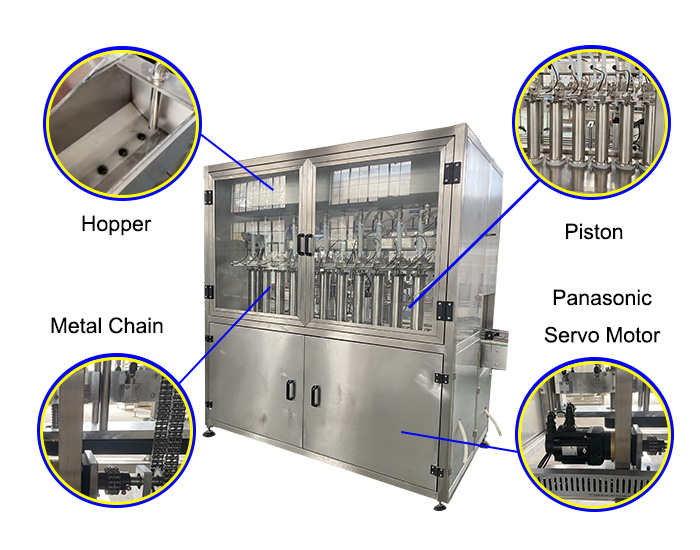

It adopts PLC+man-machine touch screen control system. PLC can save parameters for subsequent use, and operators do not need too many complicated operations.

It adopts Mitsubishi servo motor to drive the plunger pump, which has fast speed and high filling accuracy; the filling volume adjustment is more convenient, just enter the filling volume from the touch screen.

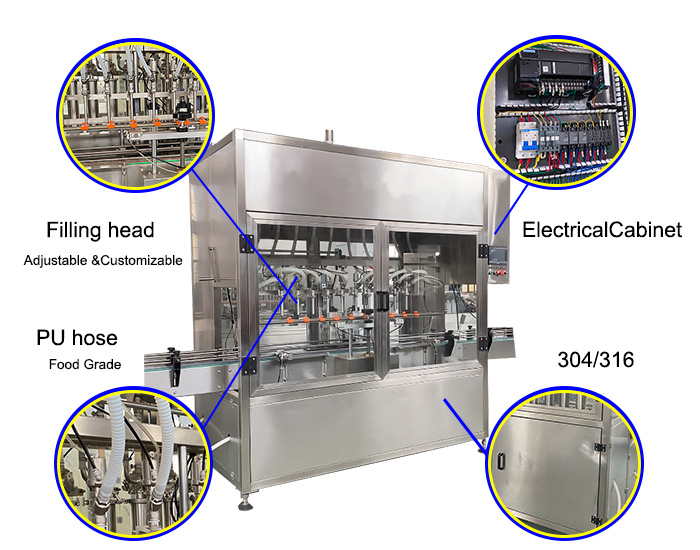

Machine Features:

1. Our edible oils are highly viscous and adaptable to the poor fluidity of peanut and palm oils in winter due to low temperatures. We feature insulated piping, maintaining temperatures between 60 and 80°C, and a large-bore piston pump to prevent solidification.

2. For oils prone to foaming, our factory utilizes defoaming control, utilizing low-pressure filling, a tapered splitter nozzle (to reduce shock), and a vacuum defoaming chamber to prevent underfilling and spillage.

3. We design and manufacture our machines with our customers in mind, striving to improve production efficiency and minimize oil loss. We utilize a high-precision mass flow meter (±0.2%) or gravimetric filling (≤5g accuracy for a 5L barrel).

4. We also feature an anti-drip design with a back-suck valve and Teflon-coated nozzles to maintain cleanliness and prevent cross-contamination.

We provide filling machines and capping machines.

We support customization and have a professional team and experienced workers.

Want a cooking oil filling machine, but don't know how to choose the right one?