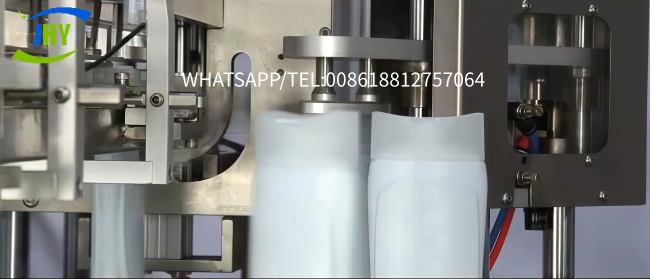

Shampoo filling equipment details:

Our factory has been making shampoo filling equipment for some time, and we've handled nearly every challenging material and bottle shape on the market. Honestly, filling shampoo isn't a snap-and-done affair—watery, thick, with pearlescent particles, and prone to foaming—any of these can overwhelm ordinary fillers.

Our shampoo filling system is built on two core principles: accuracy and durability. Accuracy means that whether filling a 200ml family bottle or a 50ml travel size, each bottle is precisely dosed, with a maximum error of no more than 0.5%. Durability means that whether your material is watery or thick enough to stand upright, this system can push and fill smoothly, without clogging or spraying everywhere.

Our shampoo filling equipment also has a way to handle foam. The specially designed slow-flow filling and defoaming circuits minimize the impact of liquid during filling, allowing the liquid to fall smoothly into the bottle, resulting in significantly less foam. The bottle threads remain clean, eliminating any stickiness, and making subsequent bottle cleaning much easier.

Changing bottles? It's a common occurrence. Round, flat, tall, short, plastic, glass... this shampoo filling equipment can accommodate them all. We've implemented a quick-change mechanism. Simply adjust the track and replace a set of grippers, and production can be switched in 10 to 20 minutes, eliminating any major hassles.

We strive to make it user-friendly. The touchscreen interface is intuitive, making parameter settings and recipe storage easy, even for beginners. We also support remote video debugging, allowing users to easily troubleshoot minor issues through a single glance, minimizing production delays.

A few points you might be concerned about:

The filling speed ranges from 60 to 300 bottles per minute, depending on the bottle type and material properties.

The pump and valves are made of corrosion-resistant materials, making them durable even to shampoo particles.

The entire machine consumes only about 3 kilowatts, making it energy-efficient.

If you'd like to add automatic capping, locking, or labeling capabilities later, we've reserved space and interfaces for easy expansion.

Ultimately, you're not looking for a pile of steel; you're looking for a dedicated, reliable operator who can work online every day without getting mad or failing. If you're unsure, please bring your bottles and shampoo to our factory for a trial run. Filling a few cases and seeing the results is more convincing than anything else.