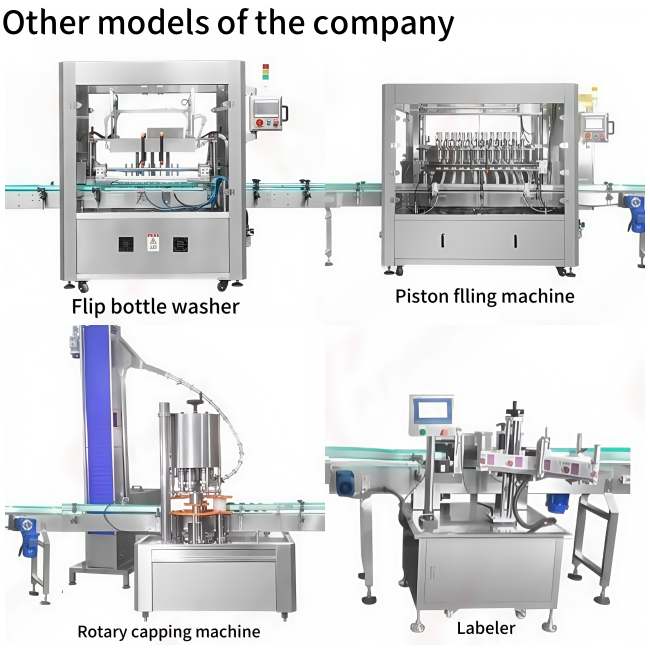

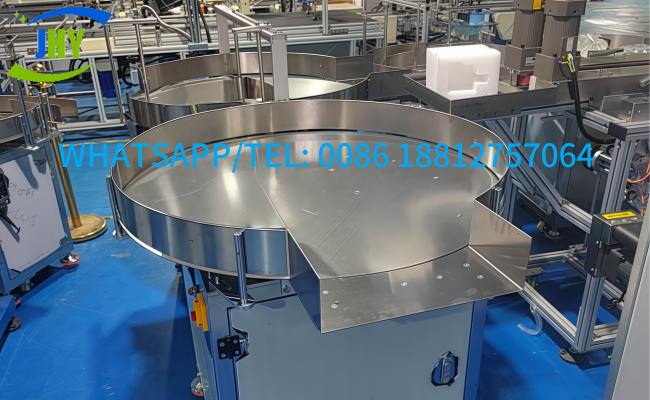

High speed bottle unscrambler reference picture picture:

Main parameters

| Production efficiency | 100-2800 bottles/h |

| Bottle cap size | 15-70mm |

| Bottle diameter | 35-130mm |

| Applicable bottle height | 50-320mm |

| Motor power | 0.37Kw |

| Orientation success rate | ≥99.2% (high-end models >99.8%) |

High speed bottle unscrambler material standards:

Contact parts: 316L stainless steel/food grade engineering plastics (compliant with FDA/EC1935)

Surface treatment: Ra≤0.8μm (anti-scratch bottle body)

Energy and maintenance:

Power consumption: 1.5~5.5kW (speed dependent)

Lubrication: maintenance-free bearings/centralized oil supply system

Changeover time: <10 minutes (modular design can be shortened to 5 minutes)

The machine of bottle unscrambler is responsible for sorting the disorderly empty bottles into order and conveying them to the filling machine in the correct direction. To improve production efficiency and save labor costs. Types include turntable, drum, belt, star wheel, etc.

The bottle unscrambler is the "first step" of the packaging production line. The bottles are slowly and evenly sorted and rotated through the turntable. The bottles are orderly placed in the channel and enter the conveyor belt through the baffle or guide rod, waiting for washing or filling.

Advantages and features of our products:

1. It is suitable for sorting bottles of various bottle types without changing the mold. It abandons the characteristics of other bottle unscramblers that need to change the mold tray for bottles of different specifications and shapes. It is more efficient and has a wider range of applications.

2. The stainless steel body and transparent protective cover can isolate the pollution of external dust and provide perfect safety protection.

3. The bottle turning system is accurate and easy to adjust and operate.